OUR PRODUCTS

The application of Chromium and Alumina Oxides (Ceramics) by either Plasma or Oxy/Gas techniques protects components from a range of wear inducing factors.

This process is particularly effective in severe operating environments such as those encountered in the Petrochemical Industry.

CERAMIC COATING PROVIDE PROTECTION FROM: ABRASION

Stray abrasive particles, caught between mating surfaces cannot gouge a hard ceramic coating.

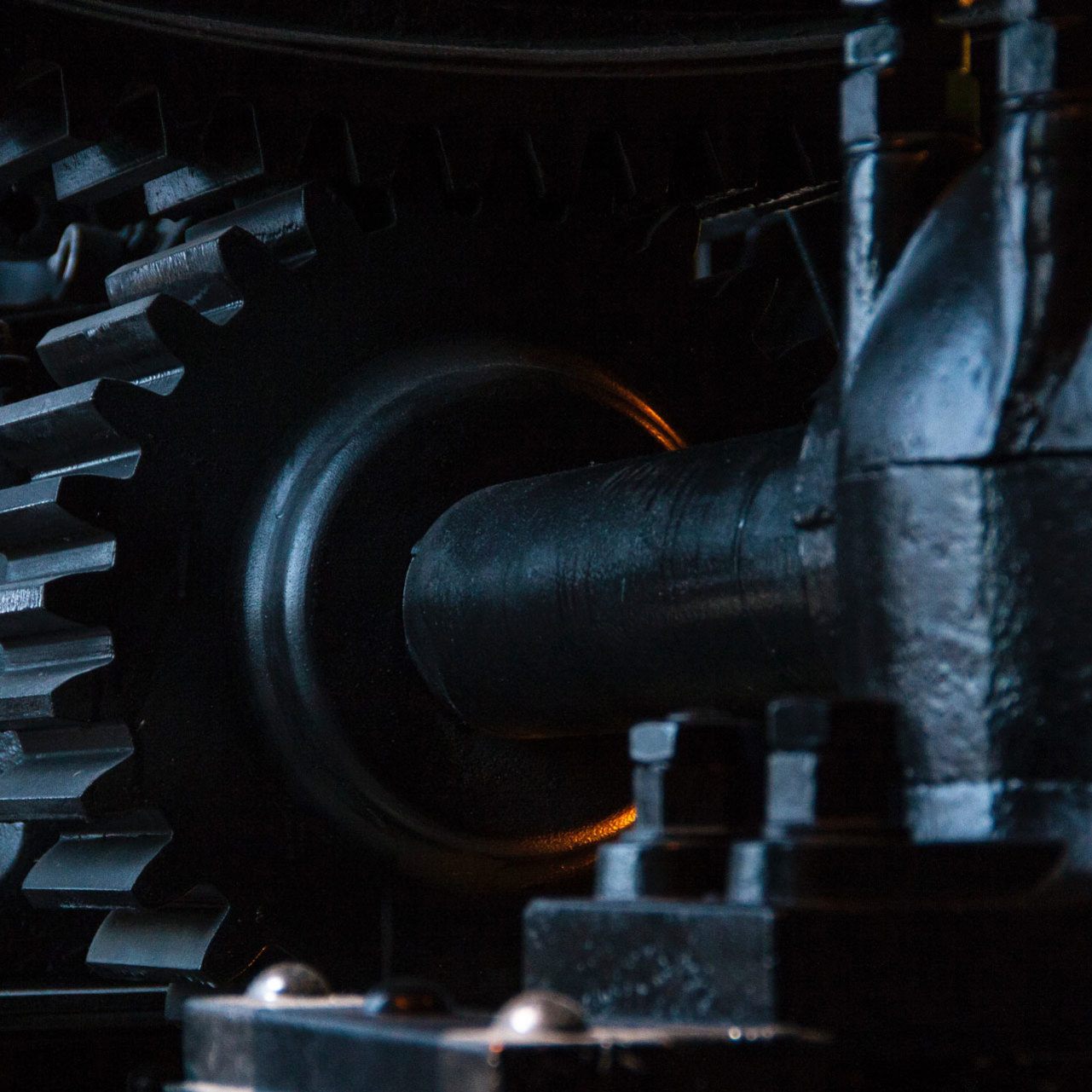

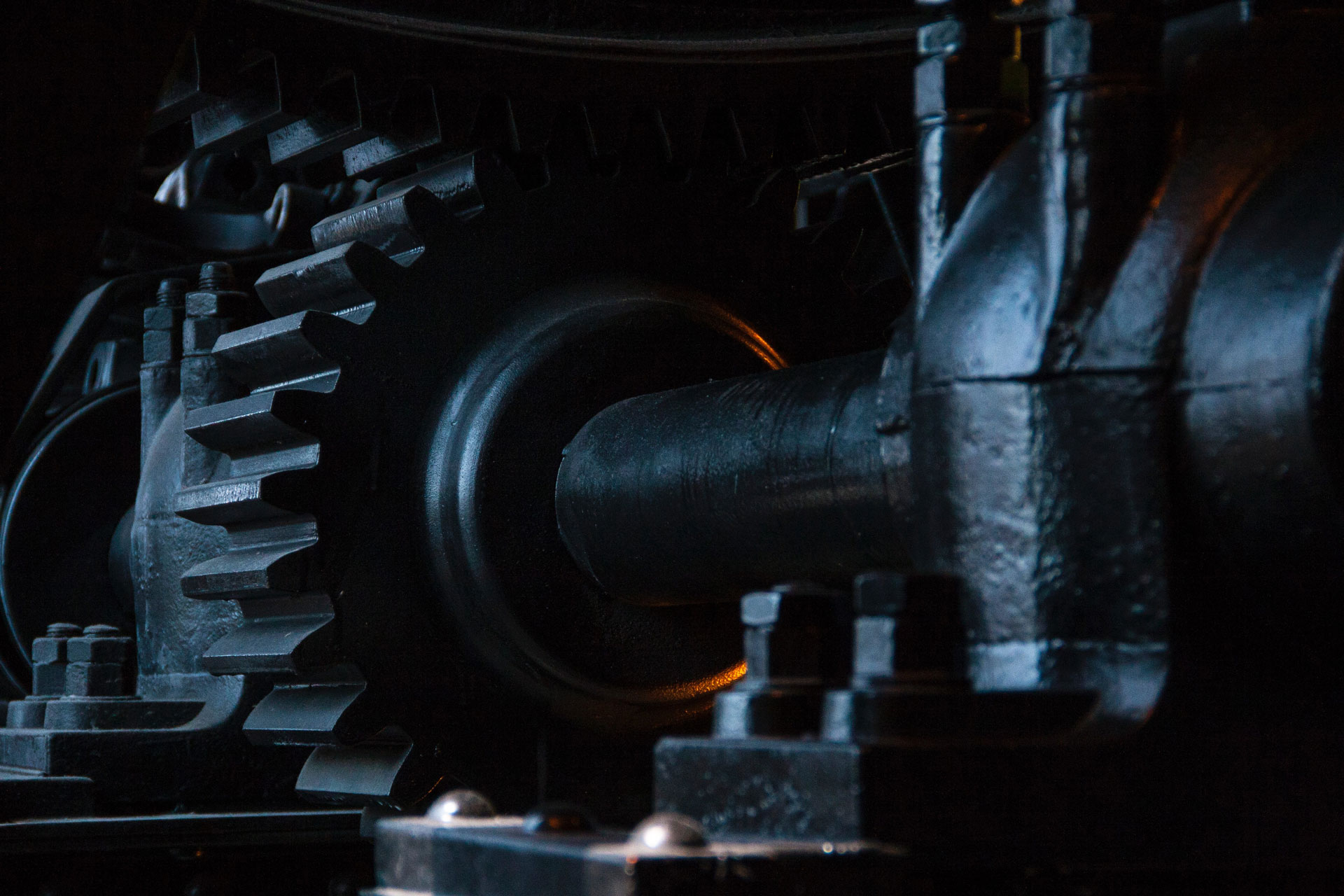

FRICTION

Marginal lubrication is countered by the low friction coefficient of ceramic coatings, also the minute surface pores hold oil and therefore act as self-lubricating reservoirs. Galling

Particle pull-out, caused by spot welding of mating surfaces is prevented by the anti-galling properties of ceramic coatings.

CORROSION

Unlike metals, ceramics do not oxidize due to heat or moisture, therefore there are no wear-causing oxides to wipe away in service.

EROSION

Abrasive solids propelled by moving liquids or gases do not erode hard tough ceramic coatings.

Applications Chromium and Alumina Oxide coatings are being successfully used in petro-chemical industry applications :

Pump impellers

Pump sleeves

Reciprocating pump compressor rods

Centrifugal pump seals

Wear and casing rings